The way an envelope is manufactured can affect how it is used or how it looks to the recipient. One of the methods offered by envelope converters to tailor the envelope for a particular use is by making them with either side seams or diagonal seams.

The “seams” of an envelope are located in the back behind the flap. All commercial size envelopes are made with one style or the other depending on certain factors. The three main factors to consider are the quantity being made, whether the mailing will be hand or machine-inserted and lastly how the envelope will be printed.

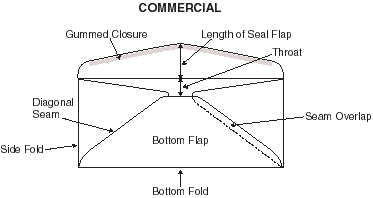

The diagram here shows a diagonal seam construction.

Diagonal seam envelopes are pre die-cut and then folded and glued in a separate process. Side seam envelopes can be made that way as well and typically are when the order quantity is below 100,000 or so. Side seam construction is more typical and common on large runs because they are made on web-style equipment. The web folding machine uses cutting knives to trim the paper before folding as part of one complete in-line process. Web machines also typically run at faster speeds than die cut machines which reduces the cost per thousand

With regard to automated inserting; diagonal seam envelopes tend to perform better with most inserters, especially those on the small to mid-size range. Larger and more sophisticated inserters can accommodate side seam envelopes with no problems although some operators still prefer diagonal seams. The rule here would be to know what the inserting application might be and what equipment is being used before deciding on which style of envelope to use. It’s never a bad idea to run a test beforehand especially if the style of construction is being changed.

The other major factor to consider when choosing the construction style of your envelope is the printing; more specifically, the printing on the back. As the diagram shows, the side seam style allows for a smooth, fold-free- panel on the back portion of the envelope. If your design requires significant printing coverage in that area which cannot be fit in between the folds and creases of the diagonal seam construction, then side seam is the way to go. While envelopes can be printed over diagonal seams, printing over the seams can cause ink build-up and gaps in the graphic images; not a good look for sure.

Consulting an envelope converter beforehand on your particular project can save you from problems after the fact. Just e mail me and I will be happy to help you figure things out for best results.